Support

After Market

Hanwha Precision Machinery Opens New Prospect in SMT Smart Factory Culture

-

T-PnP

- SM411

- SM411F

- SM421

- SM471

- SM481

- SM482

- SM451

- EXCEN

- DECAN

-

Production status monitoring & result analysis tool

- Real-time monitoring and change analysis of equipment status and production index

- Real-time error alarm & emergency production stop setting

-

T-Planner (OLP & ELITE)

- SM411

- SM411F

- SM421

- SM471

- SM481

- SM482

- SM32x

- SM451

- EXCEN

- DECAN

-

Offline programing & parts registration/management tool

- PCB program & optimal production group creation

- New part registration & parts library management

-

Power Failure Recovery Function

- SM471

- SM481

- SM482

- DECAN

-

- Intensify durability in preparation for power failure or poor power supply during production

- Reduce parts/cleaning loss caused by power failure

- Reduce quality loss by reducing the loss of expensive parts

-

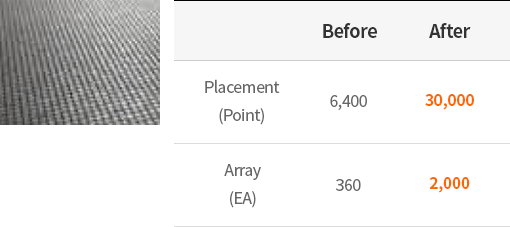

Mounting Step Extension

- SM471

- SM481

- SM482

- SLM100

-

- Placement/Array quantity expansion

- Response to large amount of mounting PCB production including LED

- Large volume of array PCB response using a jig

-

Production Data Creation

- SM411

- SM411F

- SM421

- SM471

- SM481

- SM482

- SM451

- DECAN

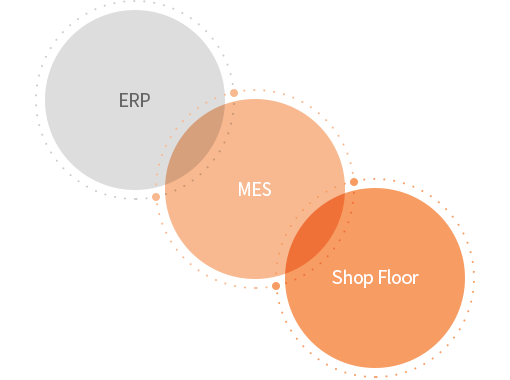

MES I/F · Production Management · Data History Management

-

MES interlocking (protocol use)

- Synchronization through data communication with customer systems

- Development is required for both MES systems and facilities

-

DB direct (stored procedure) interlocking

- Access to customer database to save the data

- Development at the facility level is required

-

File sharing method

- Save all production results as files in sharing folder

- Development at the customer system level is required

-

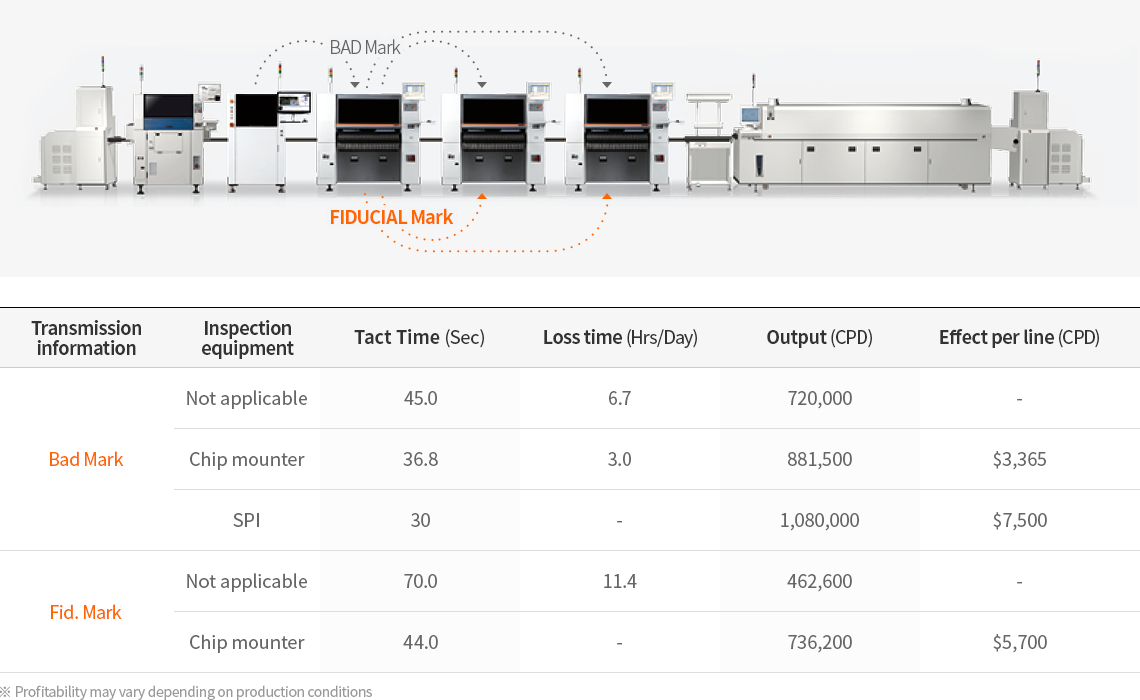

Bad/fid Mark Inspection Result Sharing

- SM411

- SM411F

- SM421

- SM471

- SM481

- SM482

- SM451

- SLM100

- SCM

- EXCEN

- DECAN

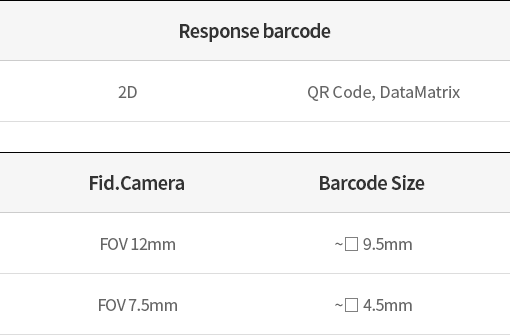

2D barcode · Mark inspection result sharing · Production loss reduction

-

Array board production process optimization

- Interlock mark inspection results among devices to reduce the Line Tact

- Secure conformity of recognition data by using barcode on PCB

-

Improve productivity by reducing basis data recognition time

- Approximately 33% productivity enhancement through the application of bad mark transmission function

- More serial arrays means a more maximized application effect